Making your own turkey call box can be a fun and rewarding woodworking project. With some basic tools and materials, you can create a handmade call that will bring gobblers running. In this article, I’ll walk you through the complete process of building a custom turkey call box from start to finish.

Choosing Materials

The first step is selecting the right woods for your box call Typically, you’ll want to use a softwood like cedar, poplar or butternut for the box itself This allows the sound to resonate. For the paddle, choose a hardwood like maple, cherry or purpleheart. The paddle strikes the box to produce the sound, so a harder wood works better.

I recommend starting with inexpensive poplar or cedar if this is your first time making a call. It’s easy to work with and tune. Once you have some experience under your belt, try experimenting with more exotic wood species.

You’ll also need basic supplies like wood glue sandpaper wood screws, a spring and finish. I prefer to use an oil-based polyurethane for protection and aesthetics.

Shaping the Box

The box consists of three pieces – the main chamber, and two end blocks. Glue up your blank using your softwood of choice for the chamber, and a contrasting hardwood for the ends. This gives a nice decorative touch.

Once the glue dries, draw the profile on the wood. Cut out the shape using a band saw or jigsaw. I like to angle the sides 5-7 degrees for a tapered effect. The exact dimensions are up to you, but keep the bottom around 1″ wide. The angled sides will make the top slightly wider.

Smooth and refine the saw cuts with some coarse sandpaper. Pay close attention to creating straight, flat surfaces for a professional look.

Hollowing Out the Sound Chamber

The next step is hollowing out the inside of the box to create the sound chamber. I use a Forstner bit to remove most of the material, being careful not to make the walls too thin.

Angle the drill press table 10 degrees so the chamber tapers from top to bottom. This helps create the ideal acoustics. Take your time removing the wood in stages to get a clean interior surface.

Then, soften the upper edges of the chamber with a sanding block. Round them over slightly for a smooth paddle stroke. Avoid removing too much thickness at this stage – that comes later during tuning.

Adding Decorative Touches

Once the basic structure is complete, you can add some decorative features to personalize your call. Inlay some contrasting wood strips into the sides for a striped effect. Another option is to checker the outside by chiseling a geometric pattern.

Get creative with wood burning, carving or other embellishments. Just remember any decorative touches shouldn’t interfere with the sound. Keep the interior as smooth as possible.

Crafting the Paddle

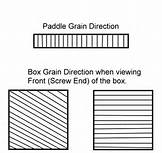

The paddle is responsible for making the sound, so choose your wood wisely. Hardwoods like purpleheart, maple and walnut work well. Cut the blank to size, allowing extra thickness for shaping.

Determine the front and back using a cotton ball test. This ensures the grain runs opposite of the box. Layout the handle shape and any inlays if desired.

Use a band saw and sander to refine the paddle profile. Add a smooth radius to the bottom edge – this contacts the sound chamber. Take your time to get a symmetrical shape.

Drill shallow holes for the lanyard and mounting screw. Countersink them slightly so hardware sits flush.

Assembling and Tuning

We’re in the home stretch now. Glue up a base for the box if making a full-length call. Install the paddle and hardware.

Here comes the fun part – tuning. Run the paddle across the chamber and listen to the sound. It’ll likely be high-pitched and raspy at first. Remove thickness gradually from the interior side walls to mellow and deepen the tone.

Aim for realistic turkey sounds like clucks, yelps and purrs. Keep sanding and testing until you achieve the voice you want. Remember, thinner walls = lower pitch.

Finishing Touches

Once tuned, apply your favorite finish to the exterior. Use thin coats of polyurethane or tung oil to protect the wood while keeping a natural appearance.

Make sure to tape off the paddle and chamber edges to prevent affecting the acoustics. Those areas should remain unfinished.

Add some chalk to the paddle if desired for slick contact with the sound chamber. Install a lanyard, and your custom turkey call is ready for the field!

Tips for First-Time Builders

Making DIY turkey calls is rewarding, but the process isn’t always straightforward. Here are some top tips to help your first build go smoothly:

-

Start with inexpensive softwoods like poplar until you get the hang of fabrication and tuning.

-

Take light passes when hollowing out the chamber. It’s easy to over-thin the side walls.

-

Take notes on paddle strokes, wood types and wall thickness. This helps recreate your favorite sounds.

-

Take your time sanding and finishing. Rushed jobs look amateur. Good looks improve the pride of a handmade call.

-

Don’t obsess over getting the perfect sound right away. Tuning takes patience and practice. Enjoy the process.

-

Ask local callmakers for advice if you get stuck. Most are happy to mentor new builders.

-

Have reasonable expectations for your first call. Skill comes from learning and experience.

As you can see, making DIY turkey calls requires careful work but isn’t too complex for beginners. With some practice at the key steps, you’ll be producing custom calls to be proud of.

The sense of satisfaction from harvesting a gobbler over your own handmade call is hard to beat. Why keep buying manufactured calls when you can create woodworking pieces perfectly tailored to your hunting style?

Follow this guide and soon you’ll have a go-to turkey talker made by you. The more calls you build, the more your skills will improve. Before long folks will be asking where they can get one of your custom turkey calls.

So give it a try – make a unique, hand-crafted turkey call this season. Customization lets you experiment and find the perfect sound. Once you start handcrafting calls, you’ll never want to go back to store-bought again.

Step 2: Wood Selection

The first step in making a box call is selecting your wood. It is best to use a soft wood for the box and a harder wood for the paddle that has a nice straight grain to make tuning easier. A few good lumber choices for the box are: Poplar, Butternut, Mahogany, Walnut, Cherry, & Cedar. For Paddles: Maple, Walnut, Cherry, Purple heart, Zebra wood, Osage, and Yellow heart.

Step 12: Box Bottom

I cut a 1/4″ thick piece of birch and 1/4″ thick ends of mahogany to match the box. Glue those together you can cut them to size after it dries.

How to make a turkey box call

FAQ

What is the best wood to make a turkey box call?

Woods like cherry, walnut, and oak offer a balanced tone, capable of producing a wide range of turkey sounds with clarity and volume.Mar 18, 2024

How to box call turkeys?

The best gobbles from a box call come by securing the handle to the body of the call with a rubber band and shaking it back and forth. To make a gobble, hold the bottom of the call with the handle pointing upward. Vigorously shake the body of the call from side to side, sending the paddle into motion.

What is the best box call for turkeys?

- Best Overall: Houndstooth Game Calls Dixie Hen Slate

- Best Box Call: Lynch World Champion Box Call

- Best Mouth Call: Woodhaven Custom Calls Ninja Ghost Mouth Call

- Best Slate: Zink Wicked Series Slate

- Best Push Button Call: Quaker Boy ‘Cyclone’ Easy Yelper

Can You Make your own box turtle Turkey call?

You can make your own box turtle turkey call if your state permits it—check with your state wildlife agency first. Be aware that no states allow you to kill the turtle for the shell—ever.

How do you make a turkey call?

Make a tube turkey call. Smooth the ends of a 3/4-inch (2 cm) PVC pipe coupler with sandpaper. Make a lip rest. Use the end of the PVC coupler to trace a circle onto a margarine tub’s plastic lid with a pencil. Cut out the plastic circle and then cut it in half to make 2 rests. You’ll need just 1 lip rest for this project.

How do you tape a turkey call?

Cut an oblong hole in the tape where it can wrap around the frame and give you a nice outside handhold to fit it to your mouth. Do not let the tape touch the latex. Slide your turkey call into the tape so the latex is exposed by the oblong hole you made. Fold the tape over and seal. Cut the tape to fit your mouth.