Bacon grease is a byproduct that many cooks end up with after cooking delicious bacon. Rather than throwing out this liquid gold, you can save it and use it to make your own lye soap. Homemade lye soap using bacon grease is simple to make, and it results in a hard, white bar of soap with excellent cleaning properties.

Overview of Making Lye Soap

The basic process of making lye soap involves combining fats or oils with a lye solution The lye reacts with the fats in a chemical process called saponification, which turns the ingredients into soap. Here is a quick overview of the soapmaking process

-

Prepare the fat or oil. Bacon grease must be cleaned and filtered before using.

-

Make a lye solution by mixing sodium hydroxide (lye) with water. Allow to cool.

-

Combine the lye solution with the melted and heated fat. Stir until thickened to trace

-

Add essential oils or other additives (optional),

-

Pour into molds and allow to set up.

-

Unmold, cut, and cure the soap for 4-6 weeks.

The exact measurements and temperatures will vary depending on the type of fat used. When making soap with bacon grease, it’s important to use the correct lye calculation for bacon fat to ensure all the lye reacts during saponification.

Why Make Soap with Bacon Grease?

Bacon grease makes an excellent soap fat for several reasons:

-

It’s free and readily available if you cook bacon regularly. No need to buy oils.

-

The high saturated fat content of bacon grease produces a hard, cleansing bar of soap.

-

Bacon grease soap lathers well and leaves skin feeling smooth.

-

Making soap provides a useful purpose for saved bacon drippings.

-

It’s a fun, homemade gift for bacon lovers!

Bacon fat soap was commonly made by earlier generations as a practical way to use up accumulated fat. Today, homemade soapmakers enjoy experimenting with bacon grease for both its performance and novelty value.

Getting Started Making Bacon Grease Soap

Before jumping into soapmaking, it’s important to take proper safety precautions when using lye, which is caustic. Wear gloves and eye protection, and work in a well-ventilated area. Keep vinegar on hand to neutralize any spills.

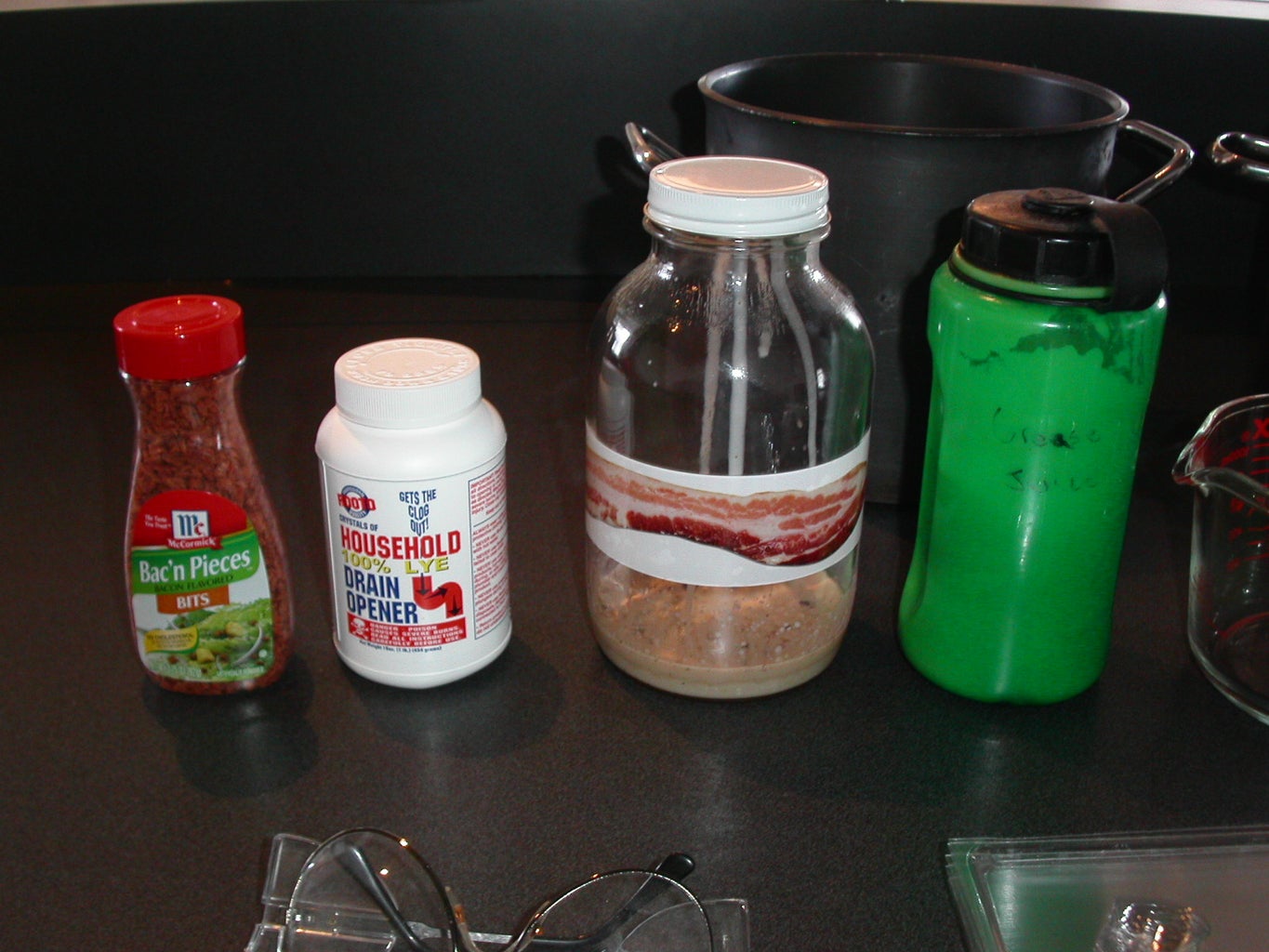

Here is a list of recommended supplies for making bacon grease soap:

-

Bacon grease – at least 12 oz for a 2-3 lb batch

-

Lye – sodium hydroxide. Purchase from soapmaking suppliers.

-

Distilled water

-

Digital scale for weighing ingredients

-

Thermometer

-

Stainless steel or glass bowl and spoon

-

Soap molds – silicone or wood

-

Essential oils (optional)

-

Eye protection, gloves, and clothing to cover skin

-

Vinegar in a spray bottle for lye spills

Familiarize yourself with soapmaking safety before starting. Work slowly and carefully when making lye soap.

Rendering and Cleaning Bacon Grease

Homemade lard or bacon fat must be properly rendered and cleaned before using for soap. Here are tips for preparing bacon grease:

-

Cook bacon until crispy to render all the fat. Drain on paper towels.

-

Pour hot grease through a coffee filter or cheesecloth to remove food particles.

-

Store cooled grease in an airtight container in the fridge or freezer.

-

To clean, melt grease and boil in water for 1 hour. Allow to cool and solidify.

-

Remove hardened grease layer and discard water. Repeat process until water runs clear.

-

Boiling with a bit of salt can help purify but too much can emulsify the grease.

-

Alternately wash hot grease in vinegar and water to remove impurities and odor.

-

Avoid overheating and always strain to remove bacon bits for best results.

It takes multiple washings to get clean bacon fat for soapmaking. Cleaned lard should be white or pale yellow with little or no smell.

Calculating the Lye Solution

To make soap, the amount of lye must be carefully calculated based on the quantity of bacon fat. Too much lye leaves a harsh soap. Too little prevents saponification.

Use a lye calculator designed for soapmaking to determine the amounts. The lye calculation or SAP value for bacon fat is about 0.1388. For example:

- 12 oz bacon fat = 340 grams

- 0.1388 x 340 grams of fat = 47 grams lye

- 47 grams lye x 2 = 94 grams water

Weigh the lye and water separately on a digital scale. Slowly add lye to the water and stir until dissolved. Allow to cool to 100-110 F.

Making Bacon Grease Soap

Once you have your prepared bacon fat and lye solution, follow these steps:

-

Melt the solid bacon fat in a stainless steel or glass pot on low heat until liquid. Heat to 100-110 F.

-

When both the lye solution and fat reach the target temperature range, carefully pour the lye into the fat.

-

Stir continuously to combine for 5-15 minutes until the soap batter thickens to trace.

-

(Optional) Add essential oils, coffee grounds, oats, etc. Stir again briefly.

-

Pour soap batter into silicone molds or wooden mold lined with freezer paper.

-

Allow soap to set up undisturbed for 24-48 hours. Unmold carefully when firm.

-

Cut bars and allow to cure in open air for 4-6 weeks.

-

Enjoy your homemade bacon grease soap!

The process takes practice, but with safety precautions, you can make excellent handcrafted soap using bacon drippings. Cured bacon fat soap produces a nice hard bar that cleans effectively.

Troubleshooting Bacon Fat Soap

Here are some common issues and how to prevent them when making bacon grease soap:

-

Soft or sticky texture – Not enough lye was used. Recalculate using the accurate SAP value for bacon fat.

-

Volcano eruptions – Batter overheated. Keep temperatures in the target range of 100-110 F.

-

Separation or oily pockets – Fat not fully saponified due to insufficient mixing. Stick blend for longer after adding lye.

-

Gritty texture – Undissolved lye particles. Make sure lye is fully dissolved before adding to oils.

-

Cracking or crumbling – Soap not allowed to set up properly before unmolding. Give soap 1-2 days minimum to harden.

-

Smell/rancidity – Fat was old or unclean. Use fresher bacon grease and clean thoroughly with multiple boils/vinegar.

Tips for Making Great Bacon Grease Soap

-

Choose thick-cut bacon for more fat. Or save drippings from multiple batches.

-

Keep bacon fat in the fridge or freezer between uses to prevent rancidity.

-

Clean fat is essential! Wash multiple times until there is no pork smell.

-

Use distilled water to prevent soda ash. Boil if using tap water.

-

Allow lye solution and melted fat to cool until both are 110 F or lower before mixing.

-

Mix the batter well to fully incorporate lye for proper saponification.

-

Add salt, coffee, oats, or cosmetic clays to make specialty bacon soap.

-

Use essential oils like eucalyptus, rosemary, lemongrass or lavender to mask any bacon smell.

-

Cure soap bars for a full 4-6 weeks minimum before use for best results.

With care and practice, you can learn how to safely make wonderfully hard and long-lasting lye soap bars using leftover bacon grease. Turn your bacon drippings into homemade soap!

Step 3: Background and Recipe

Introduction: How to Make Bacon Soap